Market Overview:

The thermal spray coating market is experiencing rapid growth, driven by expanding industrial applications, demand for surface protection and technological innovations drive growth. According to IMARC Group’s latest research publication, “Thermal Spray Coating Market Size, Share, Trends and Forecast by Product, Technology, Application, and Region, 2025-2033“, The global thermal spray coatings market size was valued at USD 10.3 Billion in 2024. Looking forward, IMARC Group estimates the market to reach USD 16.8 Billion by 2033, exhibiting a CAGR of 6.32% from 2025-2033.

This detailed analysis primarily encompasses industry size, business trends, market share, key growth factors, and regional forecasts. The report offers a comprehensive overview and integrates research findings, market assessments, and data from different sources. It also includes pivotal market dynamics like drivers and challenges, while also highlighting growth opportunities, financial insights, technological improvements, emerging trends, and innovations. Besides this, the report provides regional market evaluation, along with a competitive landscape analysis.

Grab a sample PDF of this report: https://www.imarcgroup.com/thermal-spray-coating-market/requestsample

Our report includes:

Growth Factors in the Thermal Spray Coating Market:

Thermal spray coatings are being used more in industries like aerospace, automotive, and energy. These coatings protect parts from heat, wear, and damage, making machines last longer. They can be applied to both new and old parts, helping companies save money. Because of their strong performance in tough conditions, more businesses are choosing these coatings. As industries grow and need better tools, demand for thermal spray coatings is rising across many sectors.

Industries working in rough environments need strong protection for their equipment. Thermal spray coatings create a hard layer that resists rust, heat, and chemicals. This is especially helpful for the marine, oil, and power sectors. These coatings reduce repair needs and cut downtime, helping companies save money. As more businesses try to protect their machines in smart, affordable ways, thermal spray coatings are becoming a trusted solution for long-term use and reliability.

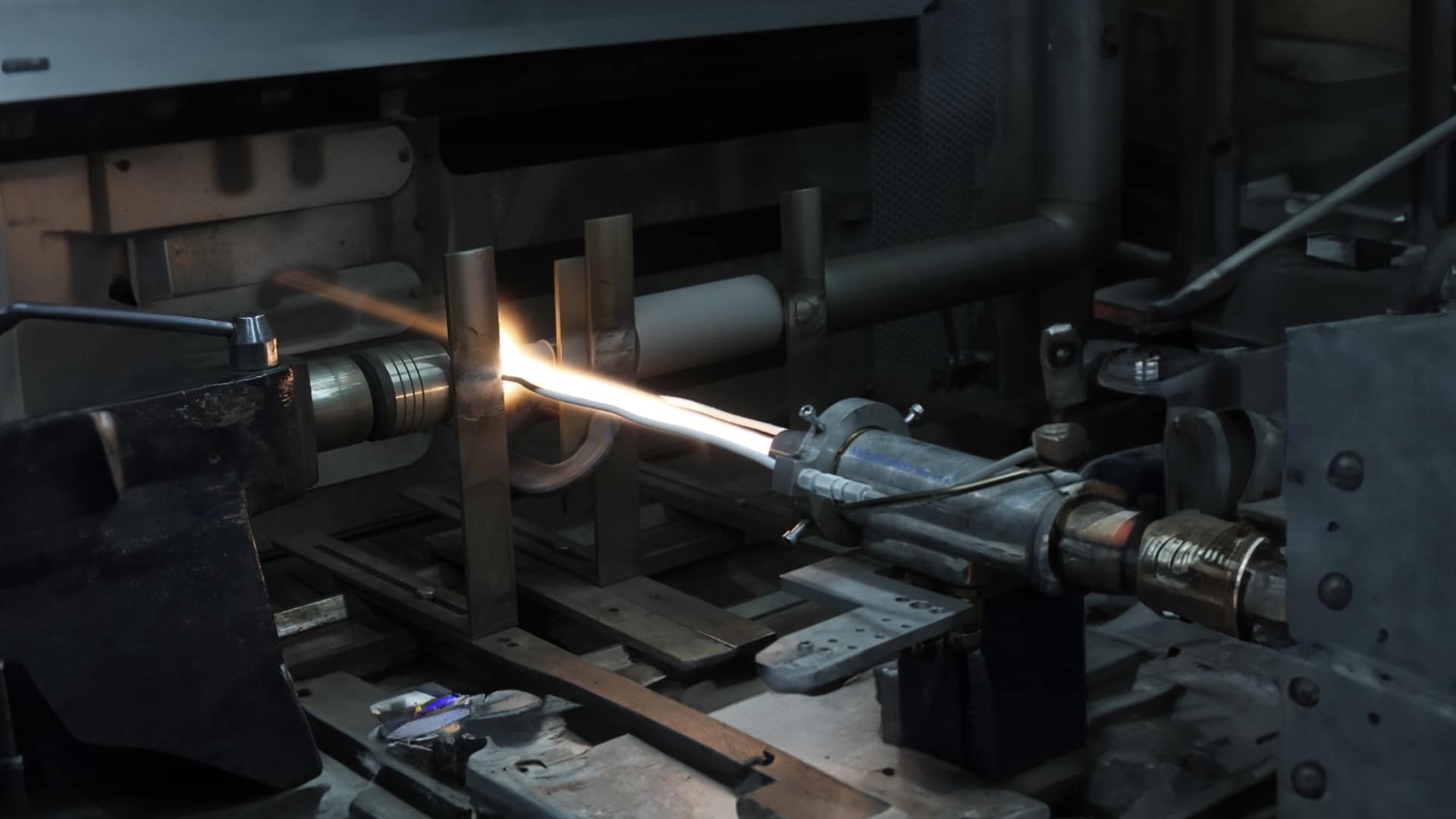

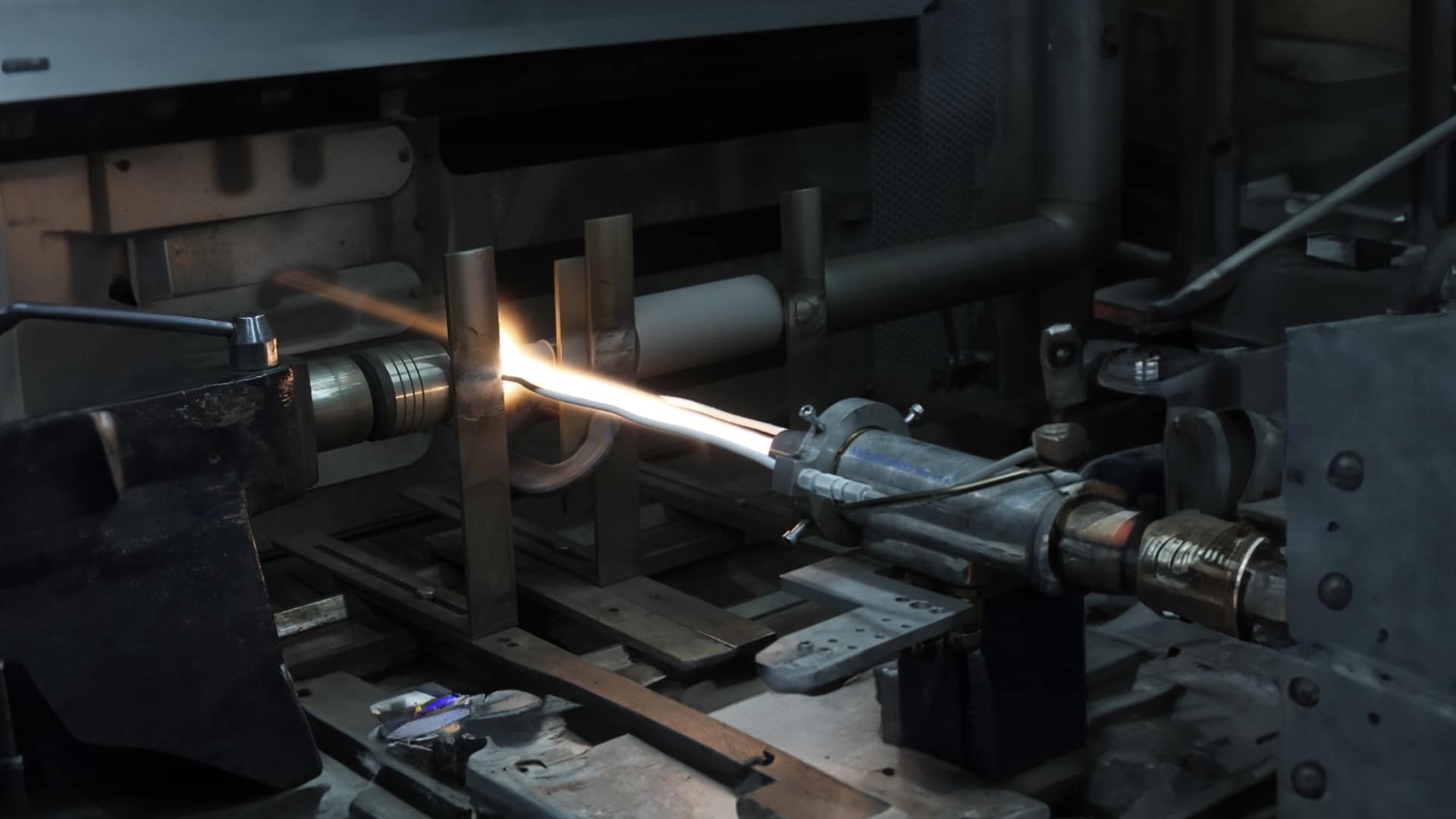

New technologies are improving how thermal spray coatings are made and applied. Better materials and spray techniques now give smoother, longer-lasting coatings. Automation and robotics make the process more precise and faster. These upgrades also lower costs and help smaller companies use the technology. As a result, thermal spray is now being used in new areas like medical devices and electronics, opening up more market opportunities and supporting steady growth in different industries.

Key Trends in the Thermal Spray Coating Market:

New coating materials and spraying methods are making thermal spray coatings stronger and more useful. Materials like cermets and nano-powders give better wear and heat protection. Updated spray methods like HVOF and cold spray make coatings stick better and last longer. These changes help meet the needs of industries that need high performance under stress. With more research and development, companies are customizing coatings for specific uses, keeping the market growing and competitive.

As environmental rules tighten, industries are choosing cleaner coating options. Thermal spray methods create little waste and don’t use harmful chemicals, making them a greener choice. Companies are now working on coatings that use bio-based or low-emission materials. These options are safer for people and the planet. Since many customers now care about sustainability, eco-friendly thermal spray coatings are in high demand and are being promoted as a smart, responsible choice for modern businesses.

Automated machines and robots are changing how thermal spray coatings are applied. Robots spray coatings evenly and quickly, reducing mistakes and saving time. They also improve safety by keeping workers away from heat and fumes. In big industries like aerospace and cars, robotic systems are now standard. These systems help make production smoother and more efficient. As more companies upgrade their factories with smart tech, automation in thermal spray is becoming more popular and essential.

Leading Companies Operating in the Global Thermal Spray Coating Industry:

Thermal Spray Coating Market Report Segmentation:

By Product:

Ceramics exhibit a clear dominance in the market due to their excellent thermal and wear resistance properties.

By Technology:

Plasma accounts for the majority of the market share as it provides precise and high-quality coatings.

By Application:

Aerospace represents the largest segment on account of the growing reliance on thermal spray coatings to enhance component durability and performance.

Regional Insights:

North America dominates the market, attributed to technological advancements and the increasing demand for thermal spray coatings across various sectors in the region.

Research Methodology:

The report employs a comprehensive research methodology, combining primary and secondary data sources to validate findings. It includes market assessments, surveys, expert opinions, and data triangulation techniques to ensure accuracy and reliability.

Note: If you require specific details, data, or insights that are not currently included in the scope of this report, we are happy to accommodate your request. As part of our customization service, we will gather and provide the additional information you need, tailored to your specific requirements. Please let us know your exact needs, and we will ensure the report is updated accordingly to meet your expectations.

About Us:

IMARC Group is a global management consulting firm that helps the world’s most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services. IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145